タイトル 1 を入力

What is an all solid-state battery? Explanation by Kanadevia, developer of the all solid-state battery AS-LiB®Contents

What are All-Solid-State Batteries? Advantages, development status and market forecastAll-solid-state batteries are a new generation of batteries in which the liquid electrolyte is replaced by solid materials.

Compared to conventional lithium-ion batteries, they have many advantages such as high safety and long life, and are attracting attention in various fields. In this article, Canadevia Corporation, the developer and manufacturer of the AS-LiB® all-solid-state battery, details the features, benefits, development status, and market forecasts for all-solid-state batteries. What is a typical all solid-state battery?Unlike conventional lithium-ion batteries, all-solid-state batteries use solid materials as the electrolyte, and are batteries composed entirely of solid materials with no electrolyte at all. All-solid-state batteries are distinguished from semi-solid-state batteries and solid-state batteries that partially use electrolyte. The features and advantages of all-solid-state batteries are briefly described below.

General All-Solid-State Battery Characteristics

General All-Solid-State Battery CharacteristicsCapacitance, voltageAll-solid-state lithium-ion batteries using flame-retardant inorganic solid electrolytes have high chemical stability and safety, and may be applicable to high-capacity and high-voltage materials that could not be used in conventional lithium-ion batteries due to issues such as electrolyte degradation and leaching of materials into the electrolyte or safety concerns.This allows for higher capacities and voltages, and is expected to improve the energy density of batteries. Life span, deteriorationIn conventional lithium-ion batteries and other batteries that use electrolyte, reactions are complex, with anions migrating at the same time as lithium ions. There are numerous degradation factors because many side reactions occur in addition to the positive reaction, such as anions depositing on the electrodes and inhibiting the overall reaction.On the other hand, in all solid-state lithium-ion batteries, only lithium ions as cations are transferred in the solid electrolyte, resulting in relatively simple reactions. As a result, there are fewer side reactions and degradation factors, and the battery system is generally said to have a long service life. Input power, output power, charging timeIn conventional lithium-ion batteries using electrolyte, lithium ions are covered with solvent, which is said to inherently resist migration and inhibit intercalation into layered compounds such as graphite anodes.On the other hand, in an all-solid-state lithium-ion battery using a solid electrolyte, lithium ions can move freely in the solid electrolyte, and it is said that lithium ions can essentially move very quickly. For this reason, some expect all-solid-state lithium-ion batteries to have higher input and output densities, i.e., faster charging and discharging. Although it can be said that rapid charge-discharge is essentially possible, all reactions in an all-solid-state lithium-ion battery occur at the solid-solid interface (point contact), so unless an ideal reaction interface is designed that is similar to the liquid-solid interface (surface contact) of a conventional lithium-ion battery, the potential for rapid charge-discharge The potential for rapid charging and discharging cannot be drawn out. What are the advantages and disadvantages of all-solid-state batteries in general?Advantages of a typical all-solid-state lithium-ion batteryAll-solid-state lithium-ion batteries offer many advantages over conventional electrolyte-based lithium-ion batteries. Improved safetyNo worry about liquid leakageSince all-solid-state batteries do not use electrolyte, there is no risk of leakage. This greatly improves safety and reliability in the design and operation of electronic equipment.They are particularly suited for products that require safety, such as medical equipment and electrical products. It also reduces the risk of fire and health hazards due to leakage of flammable and hazardous liquids. Reduced risk of fireSolid electrolytes are flame retardant, which significantly reduces the risk of ignition, smoking, and rupture compared to conventional lithium-ion batteries. In particular, they are safe in high-temperature environments and against shocks, which is advantageous in applications where safety is a top priority, such as aerospace equipment and electric vehicles.No combustible gas generationAll-solid-state batteries do not generate flammable gases due to heat generation, and there is no risk of ignition, smoking, or rupture. This allows safe operation in harsh environments and improves reliability in military applications and polar exploration.Increased durabilitylong lifeAll-solid-state batteries have the potential to achieve long life with little degradation.Solid electrolytes are chemically stable, which increases the number of charge/discharge cycles and allows for longer service life. This also reduces maintenance costs. In addition, the solid electrolyte is a substance that allows only lithium ions to move. Therefore, side reactions are suppressed and long-life batteries with little degradation can be realized. High and low temperature resistanceAll-solid-state batteries operate safely over a wide temperature range and perform particularly well in high-temperature environments. This makes them ideal for use in aerospace and polar regions such as deserts and volcanoes. They also maintain their performance in cold climates, making them suitable for a wide range of applications.High energy density potentialAll-solid-state batteries have the potential to achieve higher energy densities than lithium-ion batteries, and as the technology advances, they are expected to become high-performance batteries. This will extend the usage time of smartphones and notebook computers and improve consumer convenience. Furthermore, it is expected to be applied in emerging fields such as drones and wearable devices, where lightweight and compactness are required. Disadvantages of common all-solid-state batteriesWhile all-solid-state batteries have many advantages, they also have several disadvantages compared to conventional electrolyte-based lithium-ion batteries. High manufacturing costAll-solid-state batteries are currently more expensive to manufacture than conventional lithium-ion batteries.This is because mass production technology has not yet been established, and cost reduction is the key to widespread use. In particular, materials and manufacturing facilities unique to all-solid-state batteries are required, The current hurdle to commercialization is high because of the large initial investment required. Technical issuesContact resistance between electrode and solid electrolyteThere is significant resistance at the interface between the solid electrolyte and electrode, which hinders ionic and electronic conduction. To solve this problem, optimization of materials and improvement of manufacturing technology are needed. In particular, technologies to reduce contact resistance at the interface are required.Energy Density ChallengesAt present, it is not possible to achieve an energy density equivalent to that of lithium-ion batteries. With improved performance of solid electrolytes and development of high-density electrodes, all-solid-state batteries will promote higher energy density, reduce weight and size, and increase their usefulness in various application fields.Temperature dependenceSolid electrolytes in all-solid-state batteries exhibit reduced ionic conductivity at low temperatures, and this can affect performance. To improve performance in low-temperature environments, solid electrolyte materials must be improved and contact resistance between electrode and solid electrolyte must be reduced. Stability in high temperature environments must also be ensured.Although many technical issues still remain to be solved for all-solid-state batteries, it is expected that these issues will be solved and that all-solid-state batteries will become more widely used as well as a safer and more efficient energy solution. Comparison of common all solid-state and lithium-ion batteries Summary

What are the expected applications for all solid-state batteries in general?This section describes commonly envisioned applications for all-solid-state batteries. ▼Possible Uses

AerospaceSince all-solid-state batteries do not use materials that change state, they have the potential to provide a high level of safety and stability in space environments, where temperatures change rapidly in a vacuum, and in aviation, where atmospheric pressure changes.

Although still in the research and development stage, they are expected to play an important role in the future. Drone marketAll-solid-state batteries have the potential to enable drones to fly longer due to their high energy density and fewer side reactions. They are also expected to be safe in the event of a crash, although they are still in the development stage.

Wearable device marketAll-solid-state batteries have the potential to contribute to device miniaturization and extended battery life. Since they are ideal for safety-critical wearable devices, there are high expectations for their future development.

Military and Defense MarketAll-solid-state batteries are expected to be the power source during field operations due to their portability, high energy density, and safety. Research for their practical application is underway.

Uninterruptible Power Supply (UPS) MarketAll-solid-state batteries are attracting attention for their high charge storage characteristics, reliability, and long life, and are expected to be used as backup power sources. Research and development is underway from the present stage.

Portable ElectronicsAll-solid-state batteries have the potential to make smartphones, laptops, and tablets thinner and lighter. High safety and long life are also expected, and development is underway.

Medical equipmentIn pacemakers and portable medical devices, all-solid-state batteries offer the advantages of safety and miniaturization, and are expected to provide greater flexibility in device design. Although currently in the development stage, future applications are expected.

What is the market and future potential for all solid-state batteries in general?Market Size ForecastThe market for all-solid-state batteries is expected to expand rapidly. According to market research, the all-solid-state battery market is expected to expand significantly in the coming years. The market is expected to grow rapidly in the mid- to late-2020s as commercialization and large-scale mass production progresses. Under development by various companies for practical use and mass productionMany companies are currently developing all-solid-state batteries for practical use.

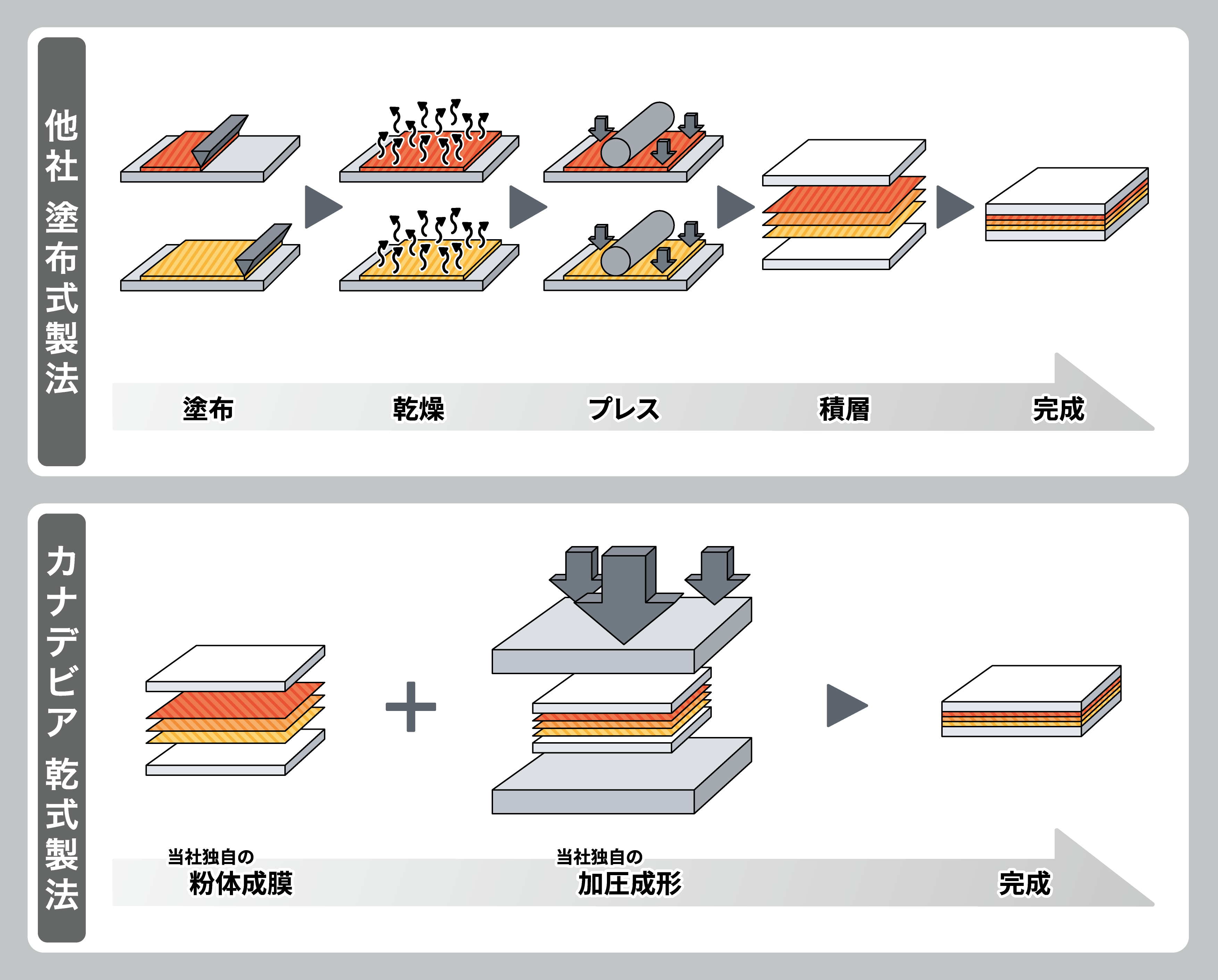

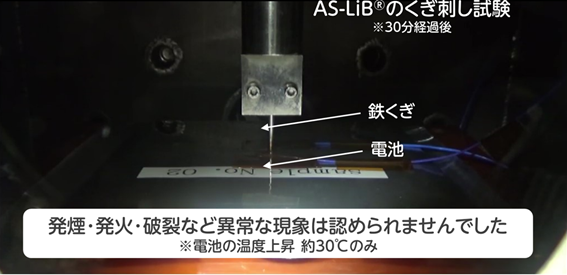

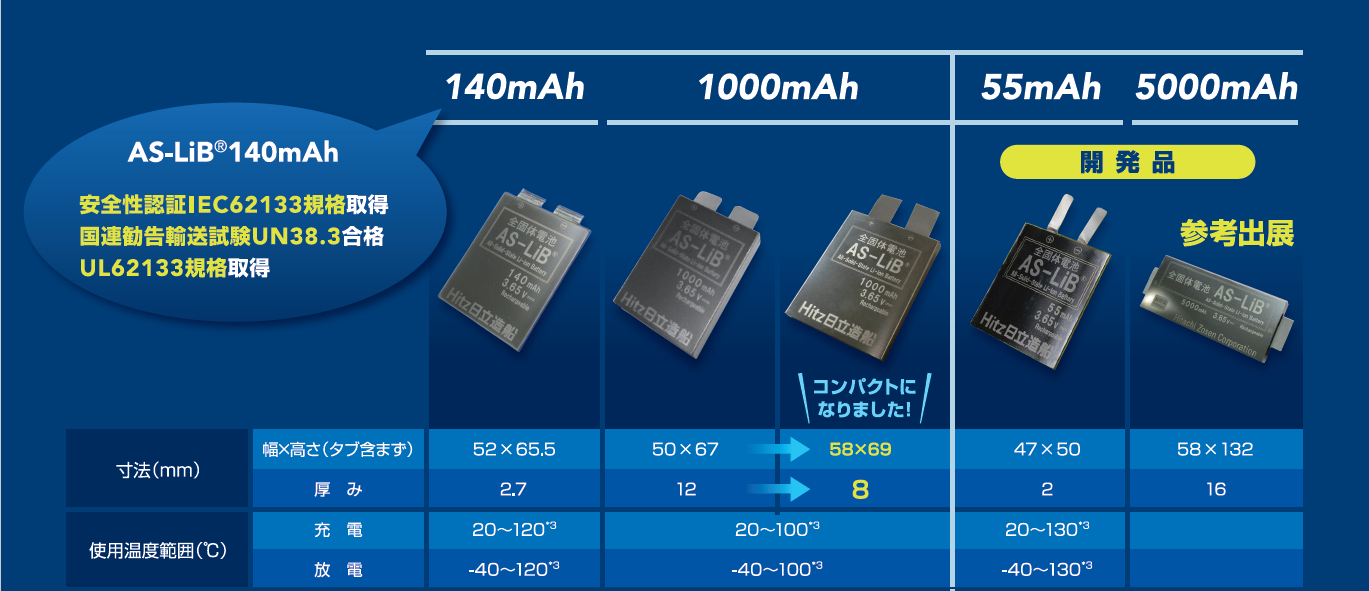

Development and research is being conducted daily by material manufacturers, automakers, and startup companies. Practical applications are underway in some applications and industriesAll-solid-state batteries have not yet been commercialized in many areas, but they are already in use in some applications and industries. For example, all-solid-state batteries are being increasingly adopted in fields that require high-performance and safe batteries, such as small electronic devices and medical equipment. About AS-LiB® All-Solid-State Batteries from KanadeviaAll-Solid-State Batteries AS-LiB® Proprietary Manufacturing MethodGeneral sulfide-based all-solid-state batteries employ the same coating method as conventional electrolyte-based lithium-ion battery production, in which the battery is formed through the following processes: slurrying of raw materials using organic solvents, coating on a current collector, drying of electrodes and solid electrolyte sheets, pressurization, and lamination. While this manufacturing process is already well established, it also creates voids after the organic solvent is removed by drying, which inhibits the formation of interfaces between particles and thus causes a reduction in battery performance. All solid-state batteries with this structure require mechanical pressure (restraining jig) to tighten the battery during charging and discharging, which is one of the major barriers to the commercialization of all solid-state batteries. Therefore, we have developed a dry all-solid-state battery manufacturing method that does not use any organic solvents or other liquids, and does not employ a coating method. By using our specialized technologies of film deposition, powder processing, and pressure molding, we are able to form the electrode and solid electrolyte layers completely in a dry process by depositing the raw powder without using any solvents and by uniform pressure molding. Since there is no organic solvent drying process, no voids remain in the electrode. This allows all-solid-state batteries to operate without the use of mechanical pressurization such as a restraining jig, even during battery operation.  Flameproof, leak-proof, and safe all-solid-state batteries AS-LiB®.Unlike conventional lithium-ion batteries, AS-LiB® does not use electrolyte, eliminating the risk of leakage. In addition, while conventional batteries use a flammable electrolyte, AS-LiB® uses a solid electrolyte that is flame-retardant, resulting in a low risk of ignition or explosion and a high level of safety. Furthermore, the low risk of ignition, smoking, and rupture has been demonstrated. In a nail penetration test of AS-LiB® 1000mAh cells, no events such as ignition, smoking, or rupture occurred, and the temperature rise of AS-LiB® was limited to about 30°C. This confirms that AS-LiB® is a very safe and reliable next-generation battery.  Low environmental impactReduction of VOC emissionsSince all-solid-state batteries do not use solvents in the manufacturing process, they are expected to reduce emissions of volatile organic compounds (VOCs), thereby reducing environmental impact. This is expected to lead to increased adoption in regions and industries with strict environmental regulations.All-Solid-State Batteries AS-LiB® Product Lineup

AS-LiB® is available in various capacity types as described above. Development is still underway for higher capacity and higher energy density. All-Solid-State Batteries AS-LiB® Applications in Special EnvironmentsThe all-solid-state AS-LiB® battery has features that allow it to be used safely in high-temperature, low-temperature, and vacuum environments. As a result, we are developing applications in industrial machinery such as semiconductor manufacturing equipment, aerospace equipment, and medical equipment. ▼Assumed Applications

All-Solid-State Batteries AS-LiB® Application Case StudyAS-LiB® 55mAh Cell Application Case Study

WAFER LOGGER (under development), a wafer-type temperature measurement device for semiconductor manufacturing equipment, is designed to measure and record temperatures without cables by mounting circuits directly on silicon wafers.

By applying AS-LiB®, it is possible to operate and measure in harsher environments (high temperature, low temperature, vacuum). AS-LiB® 140mAh cell application examplesUse in aerospace equipment (high and low temperature)Kanadevia Corporation's all-solid-state AS-LiB® batteries are configured to minimize volatile components and do not expand significantly in vacuum environments. In 2022, we launched an all-solid-state battery on-orbit demonstrator (Space AS-LiB) with AS-LiB® to the International Space Station (ISS), and subsequently confirmed for the first time in the world that all-solid-state lithium-ion batteries can charge and discharge in the space exposure environment (1.0×10-5 Pa), The system has also achieved long-term charge-discharge cycle operation for more than one year. Related Articles JAXA and Hitachi Zosen Collaboration Confirms World's First All-Solid-State Lithium-Ion Battery Charge/Discharge Capability in Space

Overview of the all solid-state lithium-ion battery used in this demonstration experiment All solid-state lithium-ion battery developed by Canadevia Size: 65mm x 52mm x 2.7mm Mass: 25g Capacity: 140mAh (used as a power source of approximately 2.1Ah by connecting 15 cells in parallel) Certification Status of Canadevia's AS-LiB® All-Solid-State BatteriesThe 140mAh cell is also UL certified (UL62133) and UN38.3 tested. In both tests, no events such as ignition or rupture occurred, and the cells passed the tests. In the future, we plan to conduct safety tests on high-capacity type cells as well. Kanadevia Corporation's role as an all-solid-state battery manufacturerWith the recent demand for innovation in the energy field, all-solid-state batteries have attracted much attention due to their high safety and efficiency. As a leader in providing innovative technology in the all solid state battery market, Kanadevia has developed its leading product, AS-LiB®. Learn about the features of AS-LiB® and the role Canadevia is playing in this field. Technical capabilities of Kanadevia Co.Kanadevia has extensive experience and advanced technological capabilities in the research and development of all-solid-state batteries. In the development of AS-LiB®, we incorporate innovative approaches in every step of the process, from material selection to optimization of the manufacturing process. In particular, we have achieved pioneering results in technologies for ensuring the uniformity of the electrode and solid electrolyte layers and reducing the contact resistance between the electrode and electrolyte. Furthermore, Kanadevia is currently studying capital investment for large-scale production of AS-LiB®, aiming to reduce costs and expand the market in the future. In addition, Canadevia plans to accelerate the spread of all-solid-state batteries by strengthening its ties with industry and through cooperation with a variety of companies. Social Contribution and Sustainable FutureKanadevia contributes to the realization of a sustainable society by providing safe and efficient energy solutions through its AS-LiB® all solid-state batteries. Through the widespread use of AS-LiB®, we aim to increase the use of renewable energy and contribute to the reduction of carbon dioxide emissions. Kanadevia's all solid-state battery AS-LiB® is setting a new standard in the energy field with its excellent characteristics and advanced technology. We will continue to develop innovative technologies and strive to realize a safe and sustainable energy society. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

タイトル 2 を入力

タイトル 3 を入力

タイトル 4 を入力